The FutureDial Blog

(1.15.2024)

The Crucial Gateway: How Receiving Operations Steer Success in Mobile Device Processing Centers

TAKEAWAY: In mobile phone refurbishing, where thousands of different phone models arrive each day requiring different handling and processing, optimizing operational processes is pivotal. This article highlights the significance of automating this initial stage at mobile device warehouses and processing centers, emphasizing improved accuracy and error reduction through automated data reading and processing. This automation not only prevents costly mistakes but also enhances downstream processes. It significantly boosts efficiency, saving time and reducing labor costs, enabling strategic resource allocation. Automated systems excel in inventory management, providing real-time tracking, regulatory compliance, and traceable histories. The streamlined process leads to satisfied customers, data security, and scalability, giving a competitive edge to mobile device refurbishing businesses. Overall, automating the receiving process goes beyond tactical improvements, representing a strategic shift that elevates operational efficiency, cost savings, regulatory compliance, and customer loyalty, ensuring long-term success in dynamic markets.

Introduction:

In the hustle and bustle of mobile phone refurbishment, where a never-ending line of deliveries of traded-in phones are drop-shipped at warehouses and processing centers, there’s one game-changer often left in the shadows: the receiving process. The receiving process for traded-in mobile phones involves several key tasks to ensure efficient handling and processing at warehouses or processing centers. These receiving tasks include inspection and verification, data wiping, recording and documentation, and other tasks before the devices are sent on for further processing like functional testing, cosmetic grading and other tasks. Receiving is the opening act in the refurb journey, and we’re delving into why smart businesses in mobile phone refurbishing are gunning to spruce up and automate this crucial first touchpoint of their operations.

In the hustle and bustle of mobile phone refurbishment, where a never-ending line of deliveries of traded-in phones are drop-shipped at warehouses and processing centers, there’s one game-changer often left in the shadows: the receiving process. The receiving process for traded-in mobile phones involves several key tasks to ensure efficient handling and processing at warehouses or processing centers. These receiving tasks include inspection and verification, data wiping, recording and documentation, and other tasks before the devices are sent on for further processing like functional testing, cosmetic grading and other tasks. Receiving is the opening act in the refurb journey, and we’re delving into why smart businesses in mobile phone refurbishing are gunning to spruce up and automate this crucial first touchpoint of their operations.

Overcoming Reluctance to Upgrade the Receiving Process

Among some refurbishing businesses, there is a reluctance to modify the receiving process, driven partly by apprehensions about potential complications. This hesitancy has resulted in a lack of significant improvements over the years in their receiving process. The receiving procedures in many cases have become outdated and unwieldy, accumulating additional requirements or tasks without corresponding updates. Regrettably, the receiving step tends to be overlooked and neglected, lacking the attention it deserves for enhancements. However, this neglect also signifies a unique opportunity for innovation, as the receiving process remains largely untouched and is ripe for transformative changes.

Configuring Receiving Processes to Fit Your Unique Requirements

Receiving is kind of the “forgotten” process step that hasn’t gotten much love over the years. Some key concerns for enhanced receiving efficiency include:

1. Meeting Tight Service Level Agreements: A refurbishing business can still adhere to its Service Level Agreements (SLAs) even with the inclusion of testing and data clearing transaction times at the receiving stage.

2. Tailored Configurations: Receiving can be configured to align with specific receiving requirements, and help automate or streamline the receiving process for greater efficiency and productivity.

3. Diverse Item Receiving: Yes, the receiving process is not limited to cell phones alone. Many processes now involve non-cellular products intentionally, such as accessories and 5G Home devices. Moreover, receiving can have the flexibility to accommodate unexpected items, providing a systematic way to record their details.

4. Rethinking the Perception of Receiving: While some management views the receiving step as “simple” and functional, demonstrating the comprehensive process benefits of integration is crucial. For instance, by combining tasks during receiving, such as device clearance and charging, you eliminate the need for additional touchpoints in subsequent stages. This may necessitate more receivers or receiving stations, but the overall headcount required is reduced, streamlining the entire process.

Precision Play: Accuracy and Error Reduction

Receiving is the first step in the refurbishment process, where “inventory” starts. Here, the receiving stage is like the conductor of the inventory orchestra. Accuracy is the spotlight, and automated systems shine by minimizing the human error that tags along with manual data entry. Think auto-reading the details of an incoming mobile device ― such as its IMEI, Make, Model, Memory Size ― ensuring the physical product delivered is exactly what was expected (i.e. if device was mis-identified upstream, label and ASN files could be incorrect.).

End-User collection Programs often get IMEI, Model and Memory Size incorrect at collection, and Bulk-Auction product could have been misidentified or misclassified by the initial processor. Therefore, it is not just about averting costly bloopers; it is about setting the stage for downstream processes to hit all the right notes.

Turbocharging Time: Efficiency and Speed

In a cost-conscious industry, time is money. Automation reduces manual handling and speeds-up the receiving process. This efficiency is vital in a competitive market where time-to-market can be a critical factor. As most operations connect the device later in the process for automated read & data clear, then why not integrate this with the receiving process to eliminate manual receiving tasks & begin the inventory transaction with accuracy?

Most operations have a time-sensitive Service Level Agreement to complete the receipt transaction at an itemized level (averages 24-48 hrs from dock delivery). So automating and streamlining the receiving tasks isn’t just about efficiency; it’s the heartbeat of meeting those ticking SLA processing time deadlines.

Budget-Friendly Moves: Cost Reduction

Money talks, and automating the receiving hustle cuts the chatter on labor costs tied to manual data entry and processing. By automating the grind, it allows the business to free-up resources to focus on tasks that need the human touch and expertise in handling.

Due to the variability and manual handling required at receiving, receiving processes have predominantly been largely human-driven, and so automating this activity “de-skills” this operation by providing a streamlined approached to incoming mobile device ingestion at the processing facility or warehouse. It’s not just streamlined; it’s cost-effective mastery in device handling.

Inventory Jugglery: Inventory Management

Automation aids in real-time tracking of inventory. Ever felt the pulse of real-time inventory tracking? Automation lets businesses dance to that beat, helping to maintain accurate stock levels, and thus reducing the risk of overstocking or stockouts. Effective inventory management is critical for optimizing working capital.

A real “ace-in-the-hole” would be a system that possesses the capability for real-time data-driven decision-making, with true dynamic or conditional processing at the device level. Having such a cutting-edge solution optimizes the intake and processing of mobile device inventory in warehouses, saving time, improving accuracy, and enhancing overall operational efficiency.

Data integrations and Dynamic Business Rule decisions drive real-time processing to direct product inventory exactly where the business needs it. No overstock, no stockouts – just a tight performance.

History on Replay: Auditable Traceability and Accountability

With automated systems, it’s not just a received device; it’s a story. Automated systems provide a clear audit trail of received devices, making it easier to trace the history and identify responsible parties when issues pop up. It’s not just quality control; it’s accountability with a spotlight. Having a system that can capture all the salient information about devices being handled at the warehouse, with information subject to lookup by any desired search parameter, greatly aids the overall tracking and audit-support compliance of a warehouse operation.

With automated systems, it’s not just a received device; it’s a story. Automated systems provide a clear audit trail of received devices, making it easier to trace the history and identify responsible parties when issues pop up. It’s not just quality control; it’s accountability with a spotlight. Having a system that can capture all the salient information about devices being handled at the warehouse, with information subject to lookup by any desired search parameter, greatly aids the overall tracking and audit-support compliance of a warehouse operation.

Enhancing auditable traceability and accountability for a receiving operation would include:

1. Comprehensive Data Capture: Implementing a system that captures not only basic information about received devices but also includes detailed metadata such as date, time, location, and personnel involved. Include relevant information about the device, such as serial numbers, batch numbers, and any unique identifiers.

2. Integration with IoT and Sensor Technologies: Integrate Internet of Things (IoT) devices and sensors to provide real-time tracking and monitoring of devices within the warehouse. Utilize sensors to capture environmental conditions (e.g., temperature, humidity) during the handling and storage of devices.

3. Blockchain Technology for Immutable Records: Implement blockchain technology to create an immutable and tamper-proof record of all transactions and interactions with the devices. This ensures the integrity of the audit trail, providing a trustworthy source for accountability.

4. Customizable Search and Reporting Features: Develop a user-friendly interface with customizable search parameters, allowing users to retrieve specific information quickly. Include advanced filtering options, such as date ranges, device types, or specific warehouse locations, to facilitate targeted searches.

5. Automated Alerts and Guided Notifications: Integrate automated alert systems to notify relevant personnel of any deviations from established processes or potential issues. This proactive approach ensures that responsible parties are aware of discrepancies in real-time, allowing for immediate resolution.

6. User Access Controls and Authentication: Implement strict user access controls to ensure that only authorized personnel can view or modify audit trail data. Use multi-factor authentication methods to enhance security and prevent unauthorized access.

7. Integration with Enterprise Resource Planning (ERP) Systems: Integrate the auditable traceability system with existing ERP systems to streamline data flow and facilitate seamless information exchange. This integration ensures that the audit trail becomes an integral part of the overall warehouse management and compliance strategy.

8. Continuous Monitoring and Improvement: Implement regular audits and reviews of the system to identify areas for improvement. Collect feedback from warehouse personnel to refine and enhance the system based on practical insights and evolving operational needs.

9. Regulatory Compliance Features: Stay abreast of industry regulations and compliance standards related to warehouse operations. Ensure that the auditable traceability system is designed to meet or exceed these standards, providing a solid foundation for regulatory compliance.

By incorporating these features and best practices, the auditable traceability and accountability system can evolve into a robust solution that not only tracks device history but also contributes to operational efficiency, risk mitigation, and overall warehouse management excellence.

Rules and Regs: Regulatory & Audit Compliance

The mobile phone industry is subject to various regulations, including environmental standards for e-waste management. In a world of rules, automation is the rule keeper, and it starts at the front-end receiving step of an operation. Automated processes can help in ensuring compliance with these regulations by accurately documenting the condition of devices and their components. Environmental standards, e-waste regulations – it’s all documented accurately. No legal hiccups, just compliance at its slickest.

Elevating Data Security Through Automated Receiving Processes

By automating the receiving process, your business can fortify the gateway against potential breaches of sensitive personal information residing on incoming mobile devices. The pivotal role of automation at this stage lies in bolstering data security, strategically confining access to confidential information solely to authorized personnel.

The ideal approach involves implementing a system that autonomously conducts data clearance on incoming devices, adhering to accepted industry-grade data erasure standards. This method ensures a standardized and uniform application of data sanitization protocols across all received devices, contributing significantly to the protection of customer data and upholding the confidentiality of proprietary information. The seamless integration of such an automated system not only enhances operational efficiency but also serves as a paramount safeguard in your company’s commitment to robust data security practices.

Flexing Muscles: Scalability

As the business grows, manual processes at the receiving step and further down the line become more cumbersome. However, for businesses with automated receiving systems, such growing pains are not an issue. Automated systems are easily scalable, flexibly adapting to increasing volumes without a proportional increase in resource requirements.

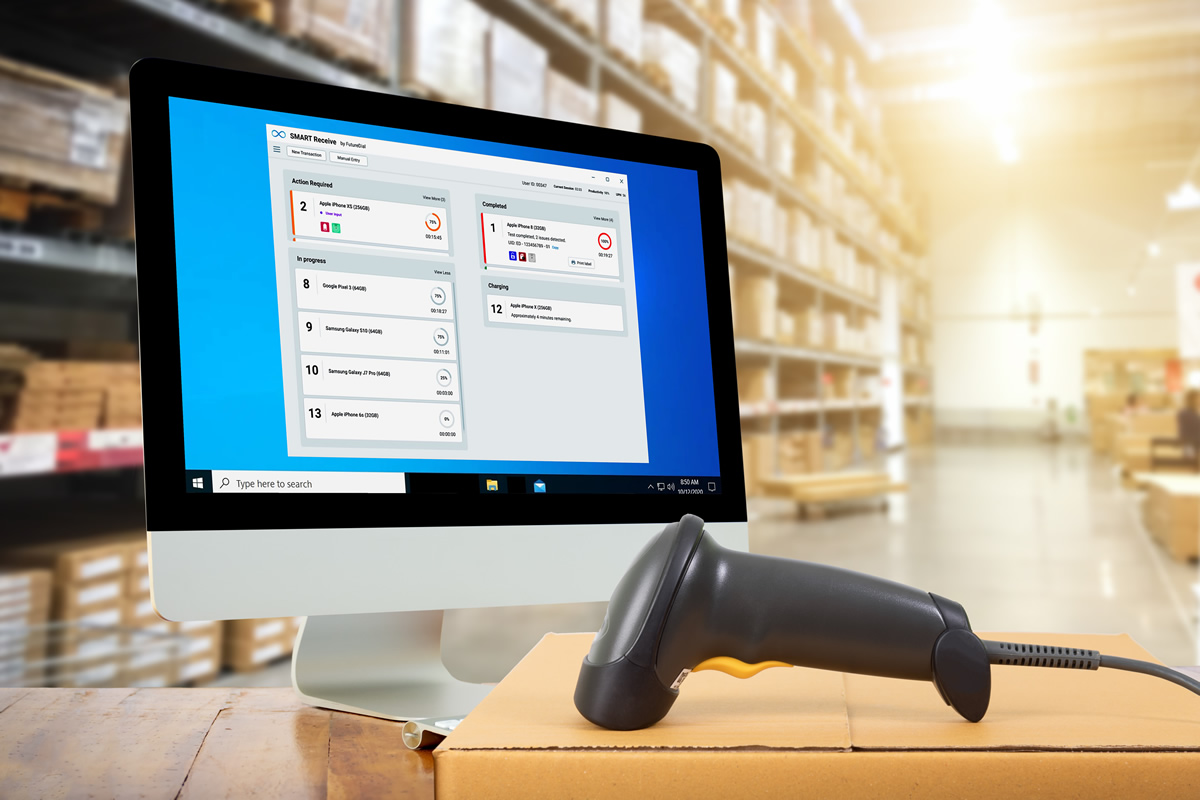

For example, FutureDial’s SMART Receive™ solution streamlines receiving tasks at warehouse and processing center operations. This system eliminates the need for pre-sorting incoming devices and efficiently manages multiple business rules simultaneously, distinguishing itself from alternative processing solutions. Unlike conventional methods that require pre-sorting and directing devices to specific stations based on testing requirements, SMART Receive™ seamlessly handles mixed products directly from the delivery dock. This capability extends beyond phones, encompassing non-cellular devices and accessories. The manual entry feature facilitates the creation of transactions for a diverse range of items without complications. A notable feature of SMART Receive™ is its real-time, data-driven decision-making capability, functioning as an adaptable smart assistant at the device level. This advanced feature not only saves time but also enhances the intake and processing of mobile devices in warehouses, ensuring faster, more accurate, and highly efficient operations.

Staying in Tune: Competitive Advantage

In a tech-driven world, businesses that embrace automation gain a distinct edge, allowing them to be agile and swift in adapting to market changes. This isn’t merely an advantage; it’s the secret ingredient that keeps them ahead of the curve, especially in an industry where technology and consumer preferences evolve rapidly. Automation isn’t just a tool; it’s the secret sauce to staying on top and maintaining a leading position in the dynamic dance of the market.

Automating mobile device receiving functions in a phone processing warehouse business offers several significant advantages over a non-automated competitor, contributing to a competitive edge in several key areas:

1. Efficiency and Speed: The advantage of automation lies in its ability to rapidly process and organize incoming mobile devices, eradicating the need for manual handling and substantially decreasing processing durations. This efficiency, in turn, provides a competitive edge by facilitating quicker turnaround times in handling devices. The accelerated pace allows for a more responsive approach to market demands, effectively mitigating bottlenecks within the processing workflow. The combination of swift processing and enhanced responsiveness positions businesses with automated systems at a strategic advantage, enabling them to stay agile and better meet the dynamic needs of the market.

2. Accuracy and Error Reduction: The advantage of automation becomes evident in its precision to accurately capture and document data related to received devices, mitigating the potential for human errors. This accuracy, in turn, establishes a competitive edge by minimizing errors across various facets of operations, including inventory management, order fulfillment, and data reporting. The result is an elevated overall accuracy level that not only streamlines internal processes but also reduces the likelihood of mistakes that could impact the efficiency and reliability of critical business functions. Embracing automated systems thus provides a distinct advantage in maintaining a high level of precision and dependability in day-to-day operations.

3. Scalability: The scalability inherent in automated systems constitutes a notable advantage, allowing them to adeptly manage an expanding influx of incoming devices without a corresponding surge in labor costs. This scalability, in turn, furnishes a competitive edge by enabling the business to seamlessly navigate fluctuations in device volumes. Automated systems excel in accommodating growth and efficiently addressing seasonal variations, positioning the business more effectively than non-automated competitors. The ability to flexibly adjust to changing demands and scale operations without incurring significant additional expenses underscores the strategic advantage of embracing automation in a dynamic and evolving business environment.

4. Cost Savings: The advantage of automating the receiving operation in terms of cost savings is noteworthy despite the initial investment required for implementation. Over the long term, the substantial reduction in labor and operational costs becomes a key element of competitive edge. A more cost-effective operation not only enhances overall efficiency but also provides the business with the flexibility to strategically allocate resources. This can translate into the potential to offer more competitive pricing in the market or to divert savings towards investments in other areas of innovation, reinforcing the business’s position as a forward-thinking and resource-efficient player in its industry.

5. Data Security and Traceability: The advantage of automation in terms of data security and traceability is evident in the capability of automated systems to enforce robust measures such as encryption and secure data erasure protocols. This translates into a competitive edge, particularly in industries where data privacy holds paramount importance. The presence of a system that guarantees the secure handling of sensitive information not only safeguards against potential breaches but also establishes a foundation for trust among customers and partners. The assurance of a secure and traceable data environment becomes a key differentiator, contributing to the overall reputation and reliability of the business in the eyes of stakeholders.

6. Adaptability to Industry Standards: The advantage of automation lies in its adaptability to evolving industry standards and compliance requirements, facilitated through convenient software updates and configurations. This adaptability forms a crucial aspect of the competitive edge, as businesses with automated systems find it more seamless to stay in compliance with industry regulations. This reduces the risk of penalties and disruptions, a significant contrast to businesses relying on manual processes that may struggle to keep pace with swiftly changing industry norms. The ability to effortlessly align with and adhere to regulatory frameworks positions automated systems as a strategic asset in maintaining operational continuity and minimizing legal and operational risks.

7. Real-time Decision-Making: The advantage of automation in real-time decision-making is highlighted by the incorporation of features such as real-time data analytics in automated systems. This capability becomes a significant driver of competitive edge, as it empowers businesses to swiftly and intelligently make decisions based on current trends and patterns. The ability to leverage data-driven insights in real-time extends its influence across strategic planning, inventory management, and responsiveness to market changes. In essence, businesses equipped with automated systems gain a distinct advantage in their agility and adaptability, enabling them to proactively navigate a dynamic business landscape with informed decision-making at the forefront.

Automate and Elevate Your Device Receiving Operations

In a nutshell, automating how you handle incoming mobile devices at your warehouse or processing center isn’t just a savvy move; it’s like having a secret weapon for a comprehensive competitive advantage. Picture this: not only does automating the receiving tasks make things run smoother and more accurate, but it’s also like giving your business a superpower. You can scale up without breaking a sweat, save some serious cash, lock down your data like a pro, stay on the right side of the rules, and make lightning-fast decisions. Businesses jumping on the automation train aren’t just making their day-to-day device receiving tasks easier; they’re far better equipped with the tools to proactively meet industry challenges, and seize opportunities over counterparts who are still reliant on manual receiving processes. Automating your receiving operation is like having a high-tech toolkit to tackle challenges, grab opportunities, and become a more agile and adaptable player in the industry.

FutureDial’s SMART Receive™ Solution: Your Key to Automating Receiving Operations for Greater Efficiency and Profitability

Leading mobile phone refurbishing businesses partner with FutureDial to implement state-of-the-art mobile device receiving automation for their operations. FutureDial’s advanced SMART Receive™ solution not only streamlines the receiving process for incoming mobile devices entering the warehouse or processing center, but also significantly enhances the overall profitability of business operations. To date, SMART Receive™ has helped businesses worldwide to streamline the receiving tasks for 6,224,252 mobile devices entering processing centers.*

Leading mobile phone refurbishing businesses partner with FutureDial to implement state-of-the-art mobile device receiving automation for their operations. FutureDial’s advanced SMART Receive™ solution not only streamlines the receiving process for incoming mobile devices entering the warehouse or processing center, but also significantly enhances the overall profitability of business operations. To date, SMART Receive™ has helped businesses worldwide to streamline the receiving tasks for 6,224,252 mobile devices entering processing centers.*

Whether you recieve mobile devices as a wireless carrier, wholesaler, refurbisher, 3PL, trade-in provider, MNO, MVNO, reseller, direct-to-consumer mobile device reseller, or play a key role in the reverse mobile device supply chain, FutureDial stands ready as your strategic partner for automation and success in this fiercely competitive market. To unlock the full potential of our innovative solutions for your business, connect with us today at sales@futuredial.com.

* Source: FutureDial SMART Receive™ cumulative processing data, as of 1.15.2024

© 2024 FutureDial Incorporated. All Rights Reserved.